Machine Introduction

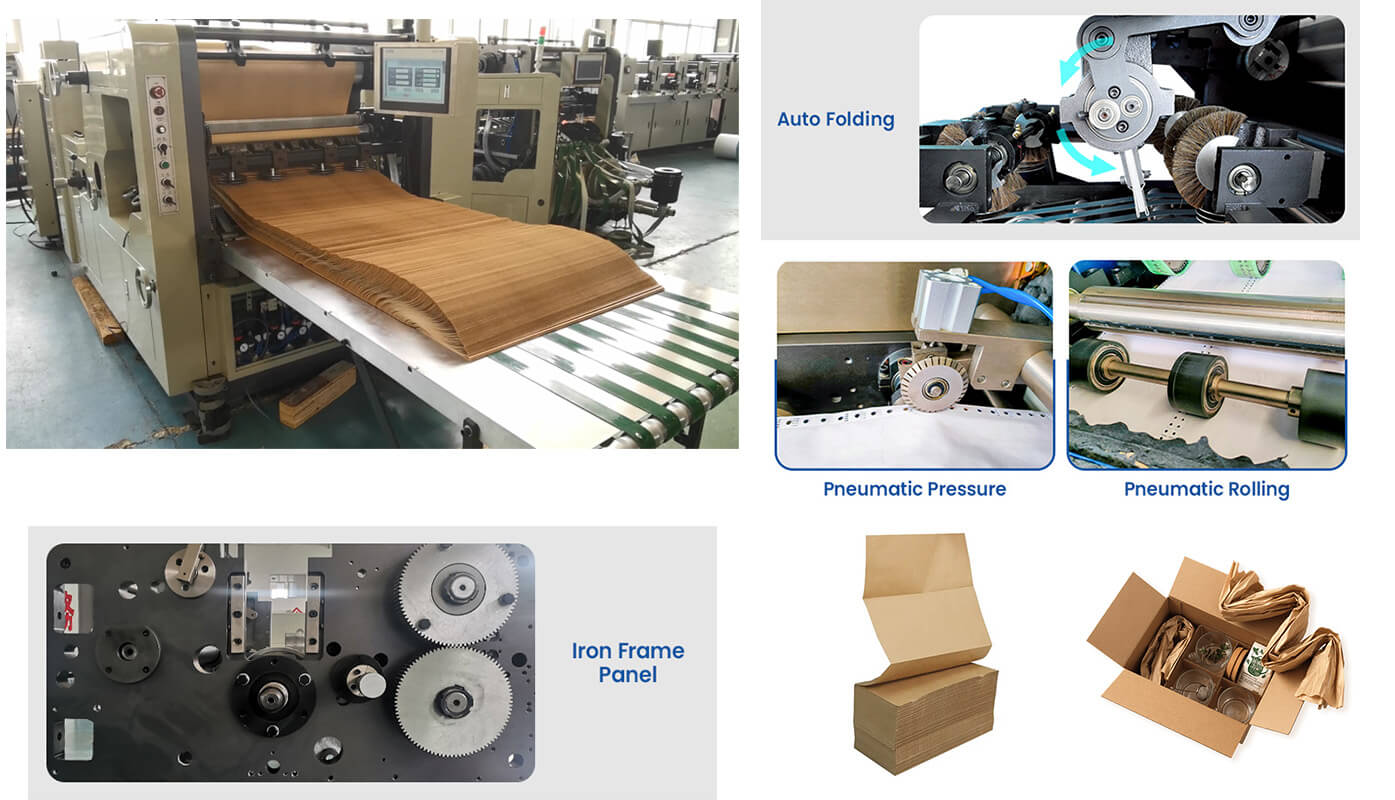

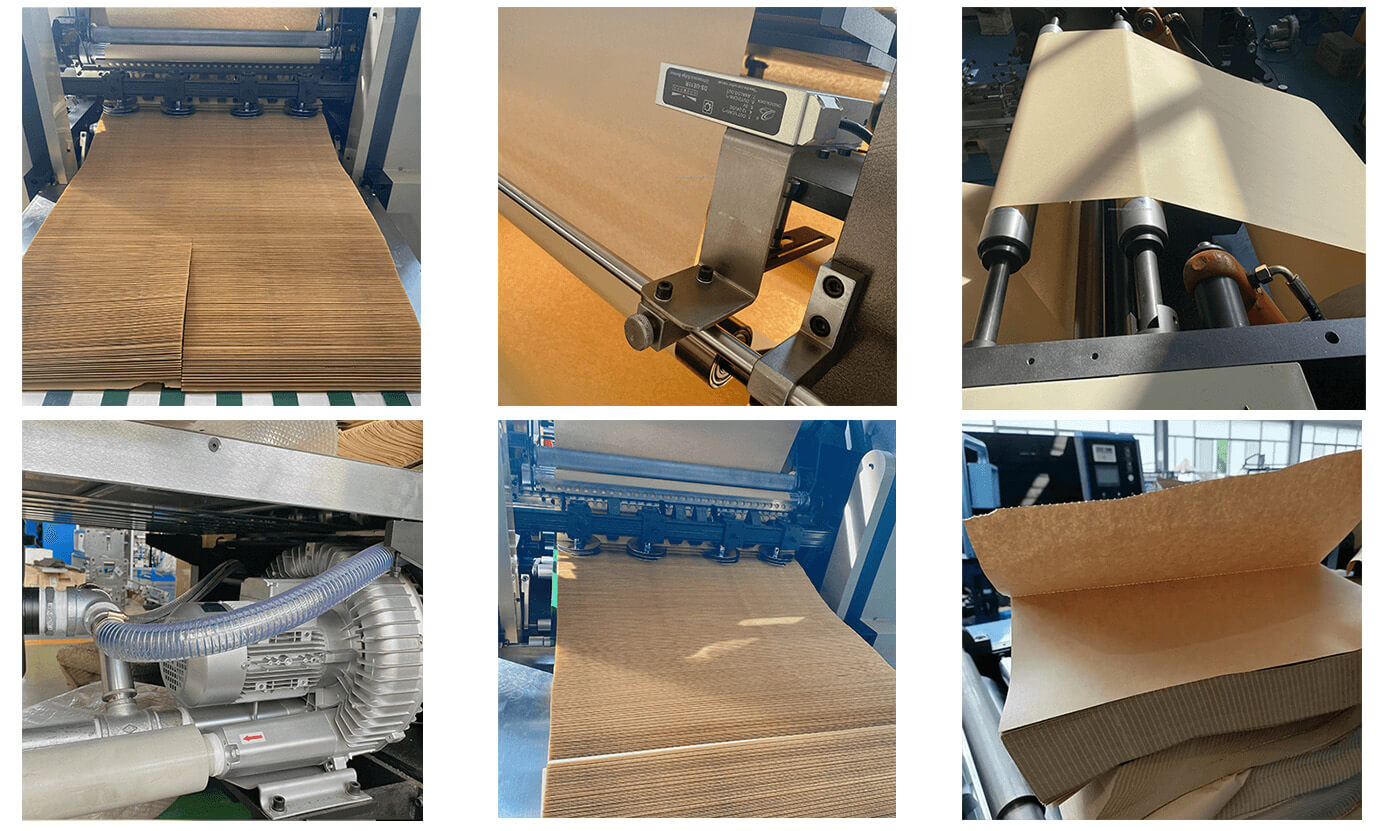

This kraft paper folding machine is designed to produce folded kraft paper rolls, often referred to as a perforating and folding kraft paper machine. Kraft paper, made from wood pulp through the kraft process, is known for its strength, durability, and shock-absorbing properties. It is widely used in industries like packaging and express logistics. The machine can be paired with equipment such as paper cushion machines to create protective, shock-absorbing packaging materials. It automates the punching, cutting, and folding of kraft paper, neatly stacking the finished sheets for easy collection.

Product Specification

| 1 | Max. unwinding Width | 780mm |

| 2 | Max. unwinding Diameter | 1200mm |

| 3 | Maximum roll weight | 600Kgs |

| 4 | Runing Speed | 5-300m/min |

| 5 | Fold size | 8-15 inches |

| 6 | Machine weight | 4500kgs |

| 7 | Machine size | 5500mm*1650mm*1700mm |

| 8 | Power supply | 380V 3Phase 5 wires |

| 9 | Main motor | 22KW |

| 10 | Paper loading system | Automatic hydraulic loading |

| 11 | Unwinding shaft | 3 inch inflatable air shaft |

| 12 | Switch | Siemens |

| 13 | Touch screen | Mikom |

| 1 | PLC | Mikom |

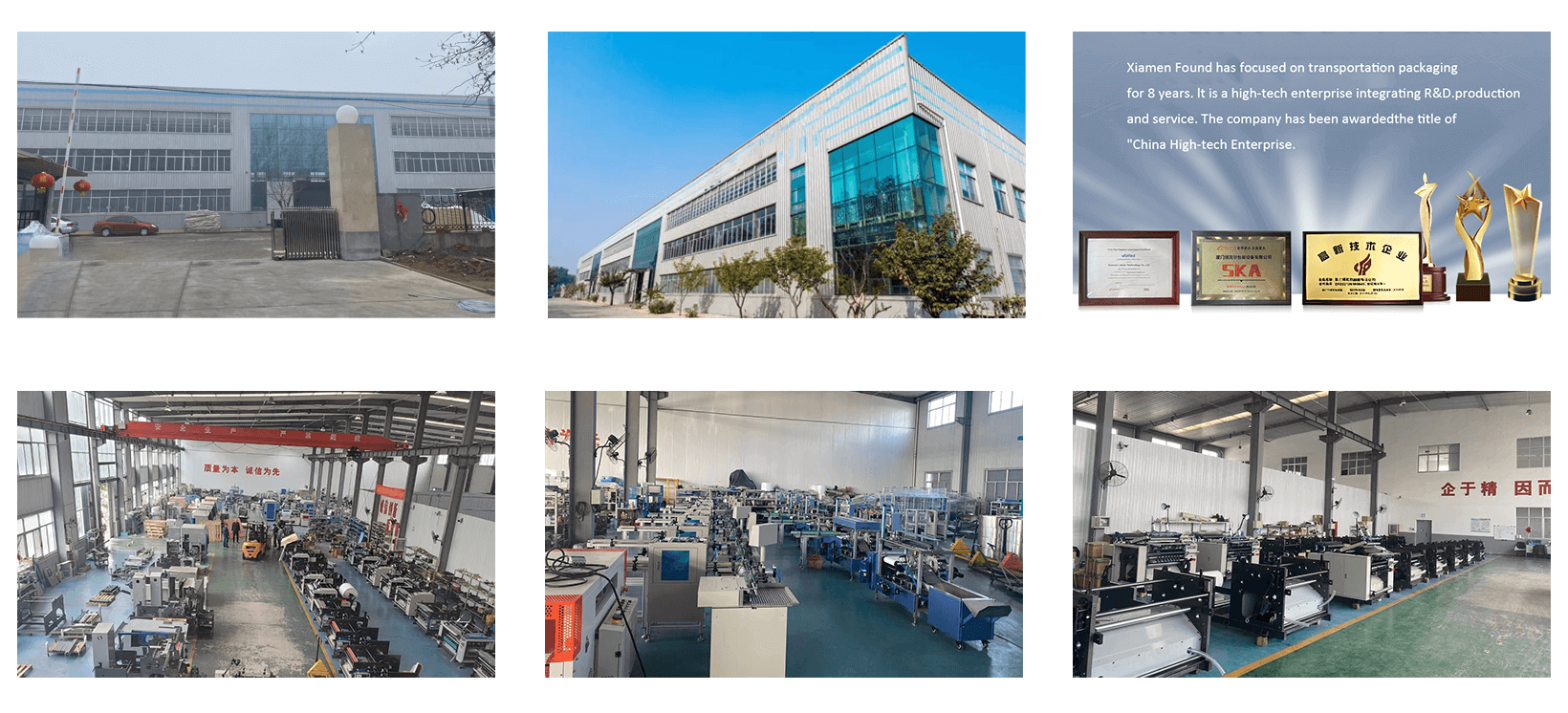

Our factory

1

Precise sales, think what you think

We analyze global paper bag production trends and sustainability insights to design versatile models that meet diverse customer needs with flexibility.

2

Excellent R& D management

Our skilled R&D team and expert management in the packaging machinery industry ensure every product meets customer needs and delivers outstanding value.

3

After-sale guarantee

We deliver comprehensive, prompt after-sales support, ensuring customers receive exceptional service every step of the way.

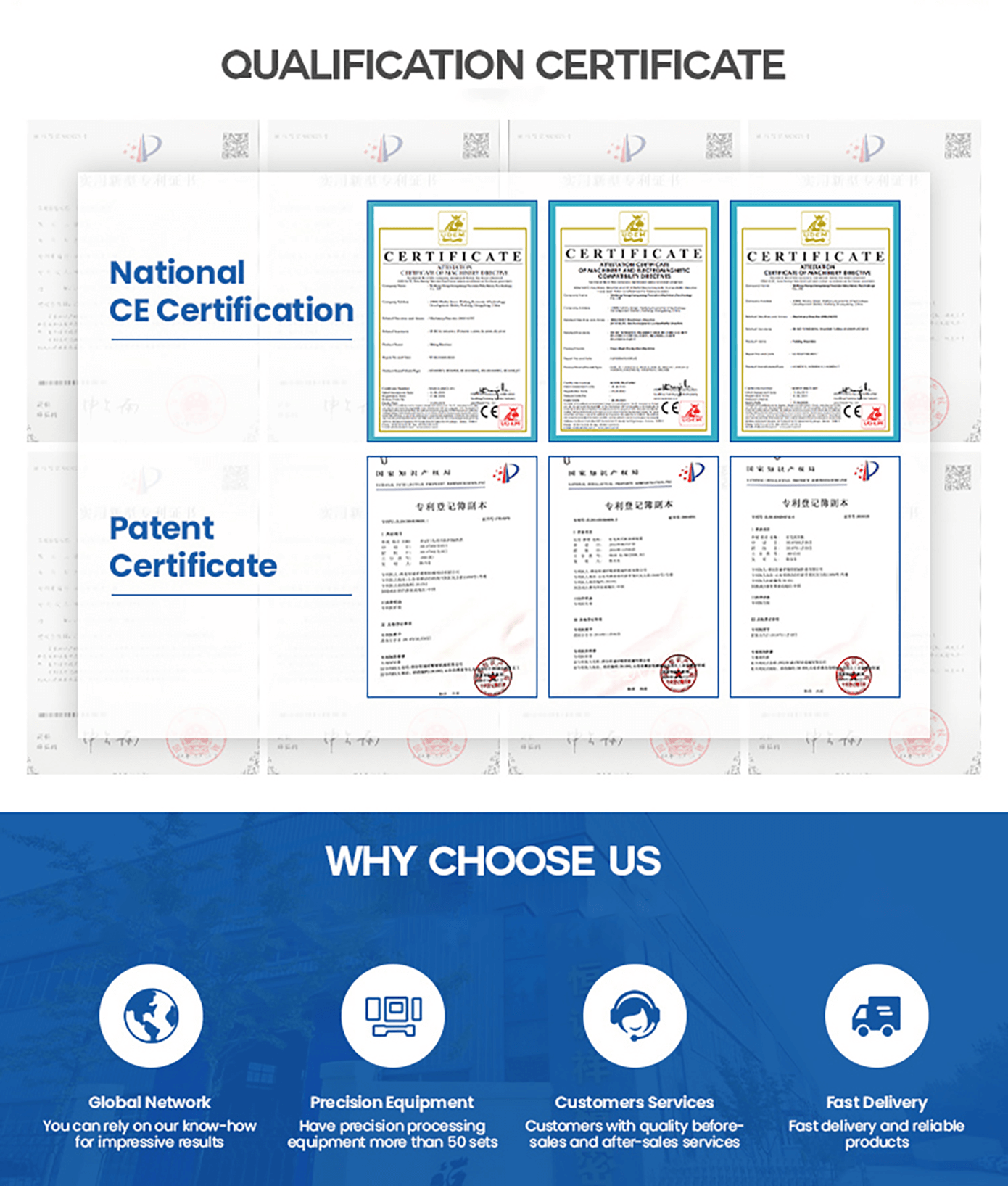

Certifications