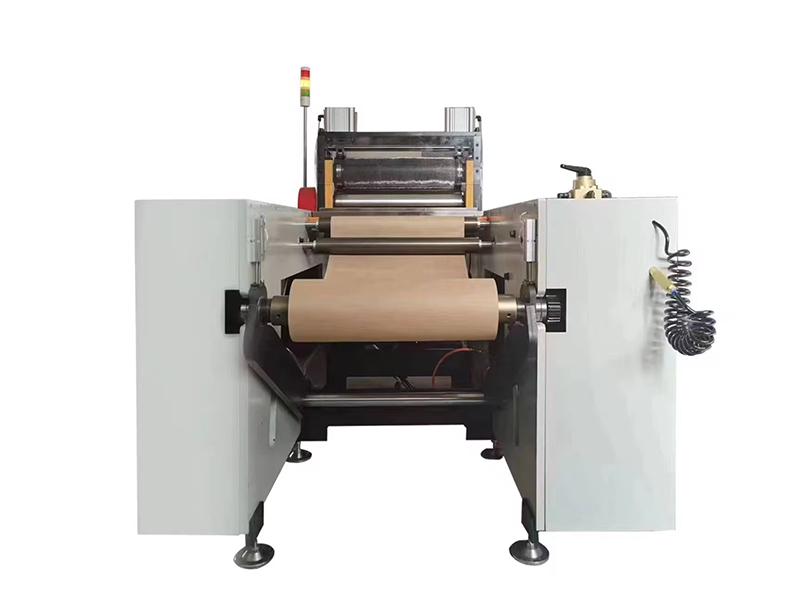

What Is Honeycomb Paper Packaging?

Honeycomb paper is a durable, lightweight, and cost-efficient packaging solution crafted from kraft paper. Inspired by the structure of a beehive, it features a unique design with a honeycomb core sandwiched between two surface layers.

These honeycomb panels offer versatile applications in the packaging industry, which will be explored further in part two of this series.

Benefits of Honeycomb Paper Packaging

Exceptionally Strong

You might wonder, “How strong can paper in a honeycomb structure really be?” Surprisingly, honeycomb paper packaging is incredibly robust—pound for pound, it’s stronger than steel. The honeycomb core and outer layers mimic the functionality of a steel I-beam commonly used in construction, making it ideal for protecting fragile items. When paired with materials like plastic, fiberglass, or metal, its strength is further enhanced. This makes it an excellent choice for packaging delicate technologies.

Lightweight and Efficient

Unlike steel, honeycomb paper is exceptionally lightweight while maintaining a high strength-to-weight ratio. This quality makes it a superior choice for packaging applications, enabling businesses to reduce shipping weights significantly without compromising durability or protection.

100% Recyclable

In addition to being strong and lightweight, honeycomb paper packaging is fully recyclable. It’s typically made from renewable and recycled kraft paper, bonded with water-based adhesive. This innovative solution uses significantly less material than traditional cardboard, yet offers remarkable compressive strength of 7 kg/cm².

Cost-Effective

Honeycomb paper is more economical to produce and purchase because it uses fewer materials than conventional packaging. Businesses also save on shipping and handling costs due to its lightweight properties, making it a cost-efficient choice overall.

Customizable

Honeycomb paper panels are highly versatile and can be die-cut into specific shapes and sizes to meet unique business needs. This allows products of various shapes to fit snugly, ensuring optimal protection. A simple slit on the back of the panel also makes it easy to bend and mold around objects, making it ideal for companies with a limited range of products.