Machine Introduction

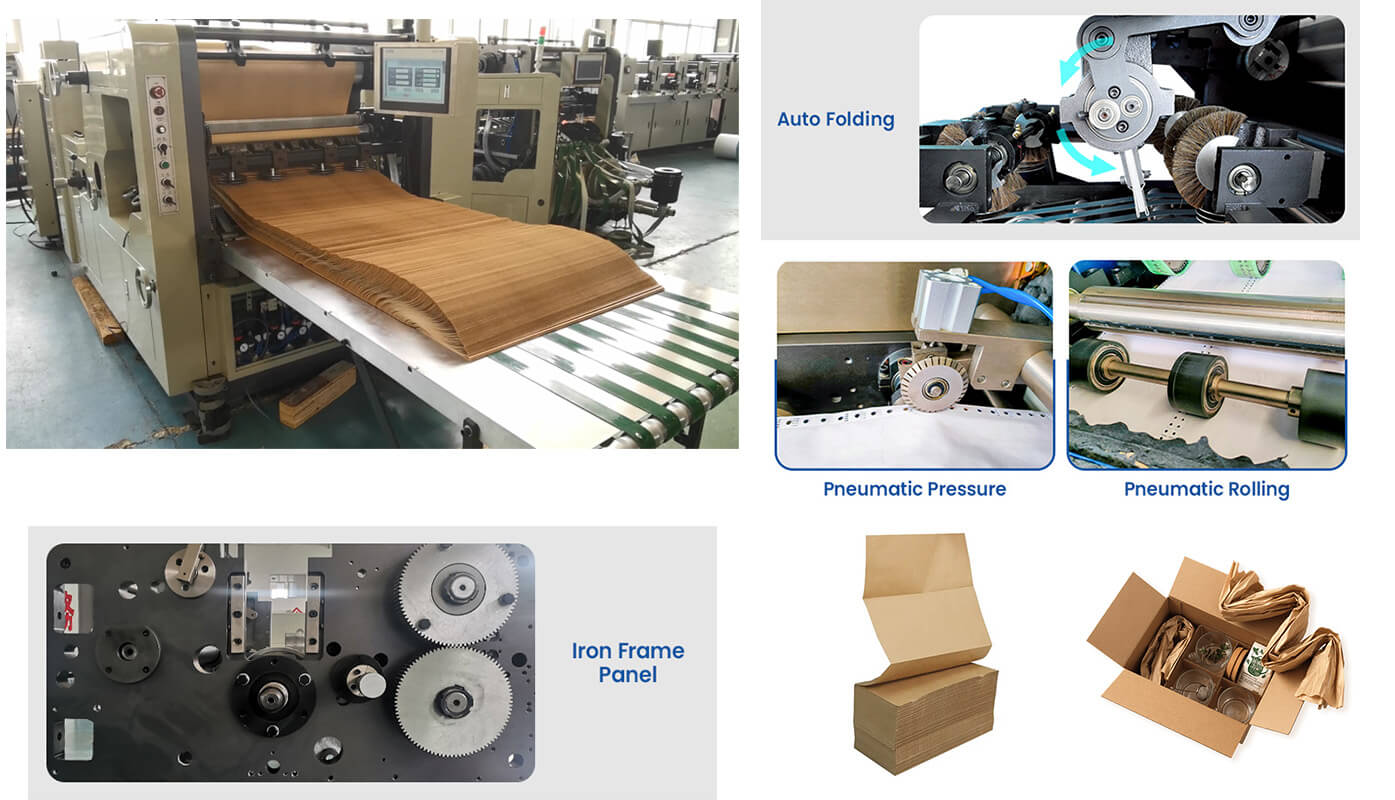

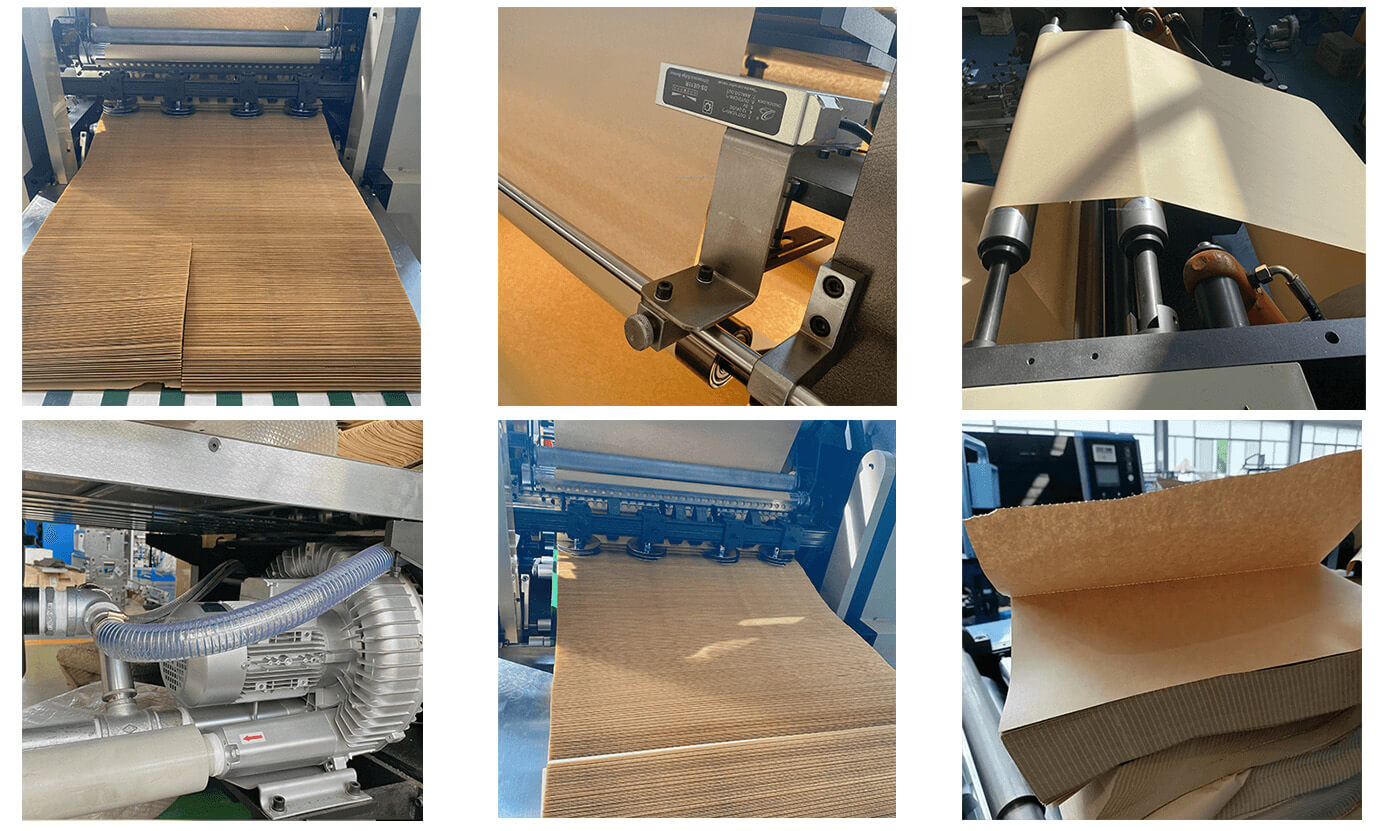

The kraft paper folding machine, also commonly called a perforating and folding kraft paper machine, is engineered to manufacture folded kraft paper rolls. Kraft paper, which is produced from wood pulp via the kraft process, is renowned for its robust strength, long - lasting durability, and excellent shock - absorbing capabilities. This makes it a popular choice across industries such as packaging and express logistics. This machine has the flexibility to be integrated with other equipment, for example, paper cushion machines. When combined, they can generate protective and shock - absorbing packaging materials. The kraft paper folding machine automates a series of operations including punching, cutting, and folding of the kraft paper. Once the process is complete, the finished sheets are neatly stacked, which greatly facilitates their collection.

Product Specification

| 1 | Max. unwinding Width | 780mm |

| 2 | Max. unwinding Diameter | 1200mm |

| 3 | Maximum roll weight | 600Kgs |

| 4 | Runing Speed | 5-300m/min |

| 5 | Fold size | 8-15 inches |

| 6 | Machine weight | 4500kgs |

| 7 | Machine size | 5500mm*1650mm*1700mm |

| 8 | Power supply | 380V 3Phase 5 wires |

| 9 | Main motor | 22KW |

| 10 | Paper loading system | Automatic hydraulic loading |

| 11 | Unwinding shaft | 3 inch inflatable air shaft |

| 12 | Switch | Siemens |

| 13 | Touch screen | Mikom |

| 1 | PLC | Mikom |

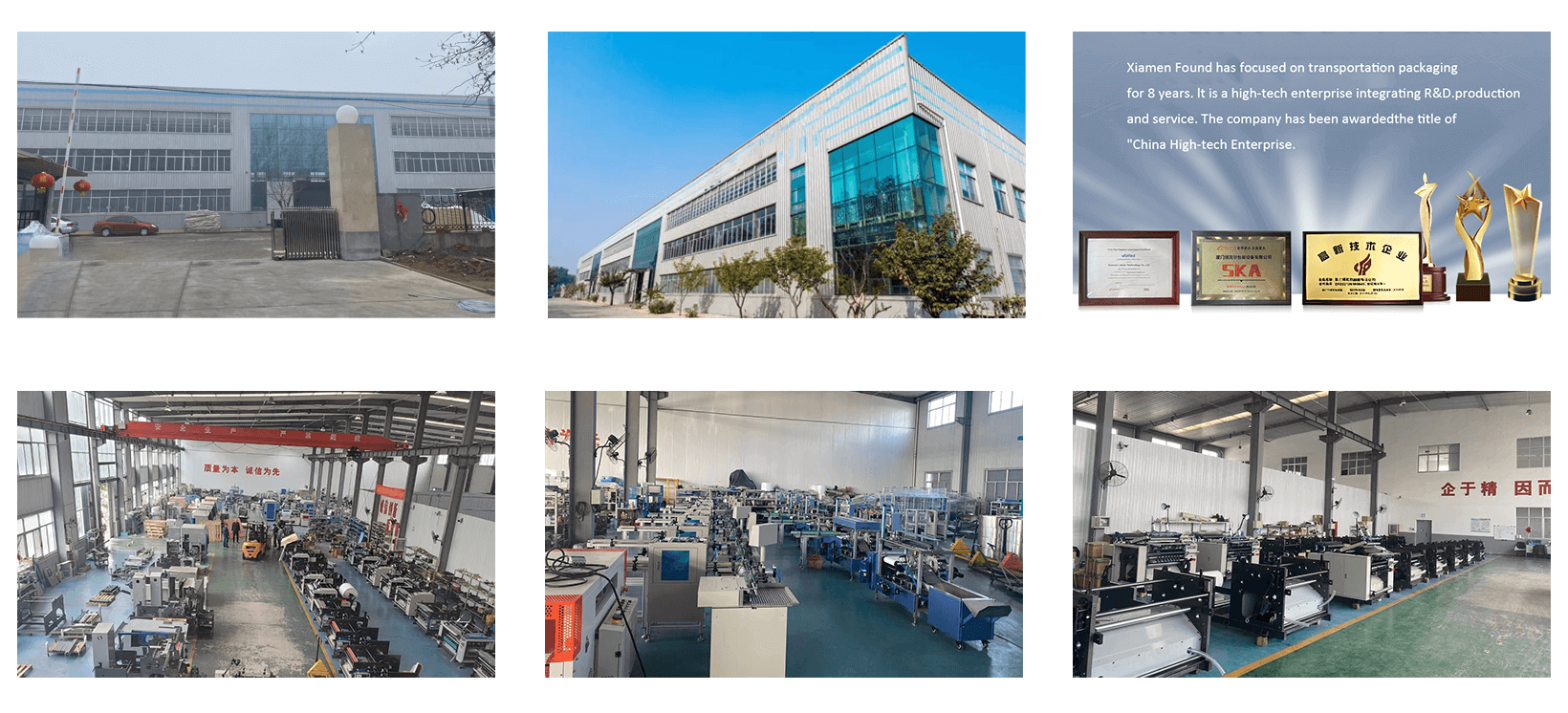

Our factory

1

Precise sales, think what you think

We analyze global paper bag production trends and sustainability insights to design versatile models that meet diverse customer needs with flexibility.

2

Excellent R& D management

Our skilled R&D team and expert management in the packaging machinery industry ensure every product meets customer needs and delivers outstanding value.

3

After-sale guarantee

We deliver comprehensive, prompt after-sales support, ensuring customers receive exceptional service every step of the way.

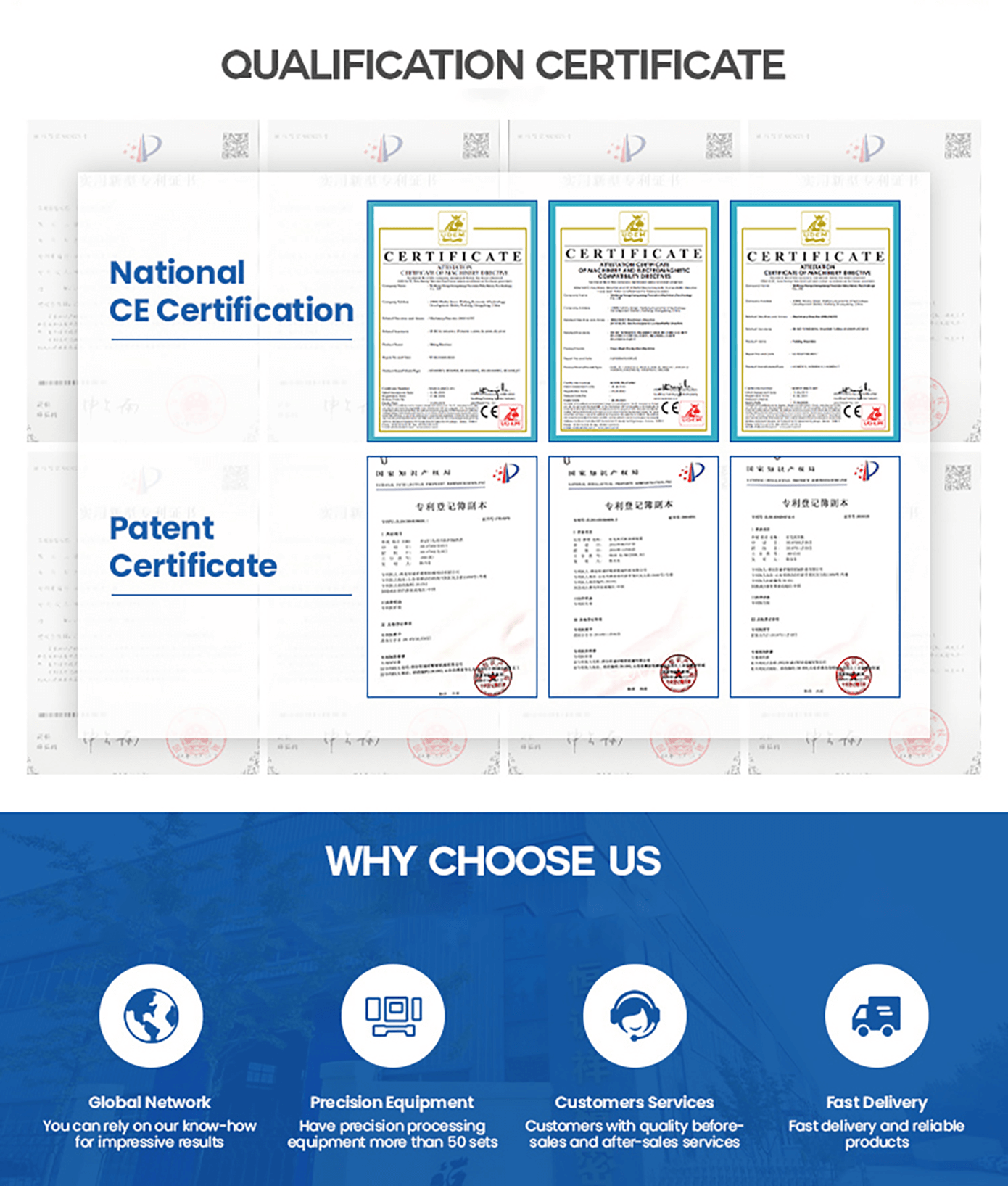

Certifications