Innovation and Sustainability: The Future of Automated Honeycomb Paper Making Machines

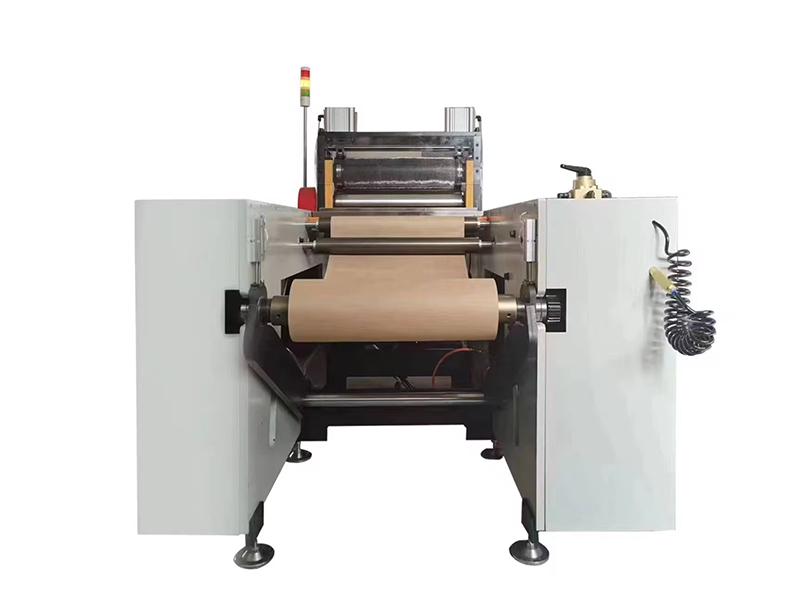

The world is increasingly embracing innovation and sustainability, particularly in industrial technology and packaging. Automated honeycomb paper making machines exemplify this shift, combining eco-friendly practices with cutting-edge technology to deliver efficient solutions.

These machines utilize renewable materials like paper to produce honeycomb structures, offering lightweight, durable, and cost-effective packaging solutions. These materials provide exceptional cushioning and protection for a wide range of products, making them indispensable across industries.

The applications of automated honeycomb paper making machines are extensive and versatile. They are vital in sectors such as furniture manufacturing, electronics, automotive, glassware, and the ever-growing e-commerce industry, where lightweight yet sturdy packaging is essential for safeguarding goods during transport.

From creating honeycomb cardboard for furniture to insulation for construction and protective packaging for various industries, these machines showcase their adaptability and immense value.

Looking ahead, the market outlook for automated honeycomb paper making machines is highly promising. The global focus on sustainability and the surge in e-commerce activities are expected to drive substantial demand for this technology.

Incorporating advancements in automation and digitalization, such as IoT-enabled real-time monitoring, will likely boost efficiency and productivity, further propelling market growth.

Investing in automated honeycomb paper production lines is more than just a step toward enhanced packaging and operational efficiency; it reflects a dedication to sustainable resource utilization and innovative practices. As this industry evolves, these machines will play a pivotal role in shaping a greener, more efficient future.